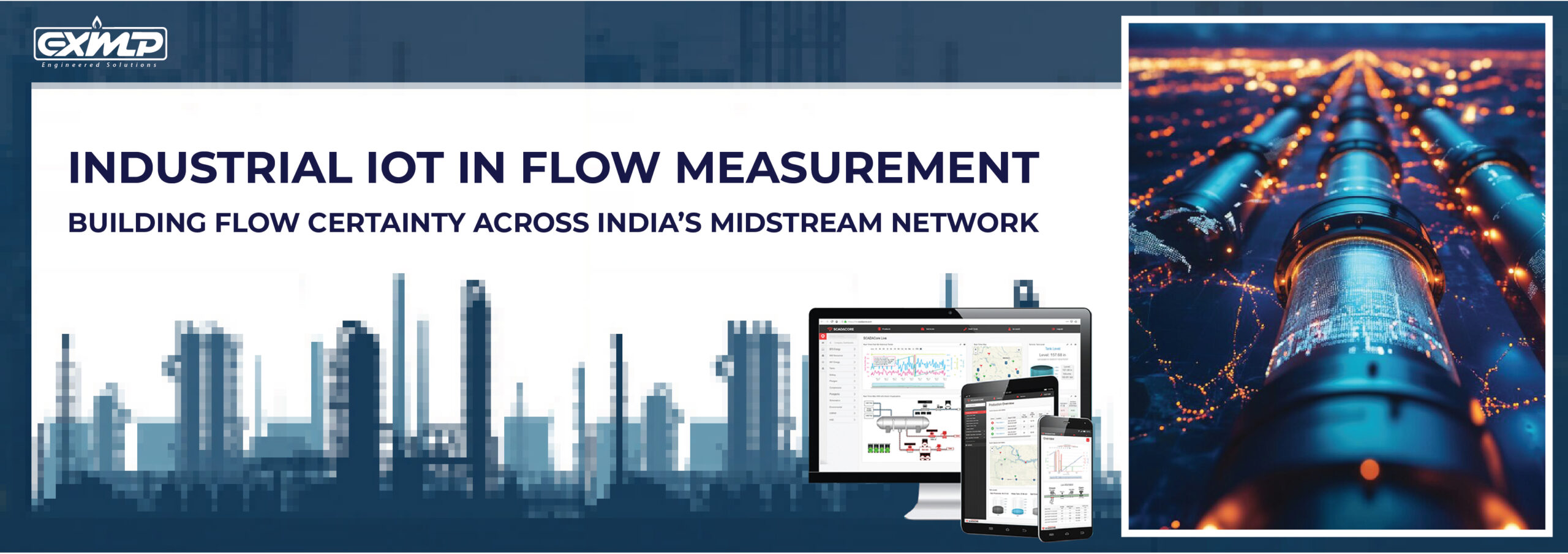

As the oil and gas industry modernizes its midstream infrastructure, precision in flow measurement is emerging as a critical driver for profitability, regulatory compliance, and emissions management. Whether it’s custody transfer pipelines, inter-company allocation, or flare gas monitoring, Industrial IoT (IIoT) is redefining how operators monitor, verify, and optimize flow across their assets.

This transformation is no longer a global trend—it’s a local imperative for operators navigating through tightening PNGRB, CPCB, and OGMP compliance requirements.

Flow meters in midstream operations—gas pipelines, compressor stations, LNG terminals, and flare systems—impact:

Traditional systems, relying on standalone meters and offline data collection, often lack real-time verification, diagnostic transparency, or environmental context.

IIoT platforms like Tekvalsys Promet, Flare.IQ by Panametrics, and Tek-Trol’s IoT Monitoring Solution offer Indian midstream operators a digital edge: 1. Real-Time Monitoring of Custody and Allocation Meters 2. Flare Flow Accuracy Under Varying Backpressure 3. IIoT in Compressed Natural Gas (CNG) and LNG Terminals

India’s regulatory momentum—from PNGRB’s metering audits to MoEFCC’s carbon registry—demands higher visibility and integrity in flow measurement. These IIoT platforms provide:

A midstream operator can realize: Industrial IoT is not a luxury—it’s a necessary step toward building a more transparent, compliant, and performance-driven flow measurement ecosystem. For Indian midstream operators, the opportunity is to retrofit smart flow visibility across the entire network—from inlet flange to flare tip.

Why Flow Measurement Accuracy Matters in Midstream

Enter Industrial IoT: Making Flow Measurement Smarter

Benefits of IIoT-Enabled Flow Measurement

Application Area

IIoT Benefit

Measurement Value

Custody Transfer Pipelines

Real-time validation of flow profiles

Reduces commercial disputes

CGD (City Gas Distribution)

Remote flow data from multiple stations

Improves LAUF tracking

Flaring Operations

CE and flow verification

Avoids methane tax penalties

Compressor Stations

Flow + vibration data

Enables predictive failure alerts

LNG Offloading

Timestamped tanker flow data

Improves unloading efficiency

Recommended Architecture for Flow IIoT in Midstream

Layer

Technologies

Use Cases

Primary Sensors

Ultrasonic (GF868), DP meters, Coriolis, Tek-Trol Vortex

Gas flow, steam, flare, cryogenic

Edge Gateways

Tek-Edge IoT Gateway, flare.IQ compute node

Data filtering, pre-processing

Analytics Platform

C-SMART Cloud, Tek-Cloud, flare.IQ Dashboard

Flow deviation detection, CE analytics

Interface & Reporting

API to SCADA, ERP, SharePoint

Daily reports, compliance logs, audit trails

Compliance-Ready and Scalable

Business Case for India’s O&G Operators

Build Flow Certainty into Your Midstream Strategy

© 2019 EXIMP

Design Made by Eximp Measurement Private Limited