DP meters have been around for more than 100 years and until now, they need to be inspected at frequent intervals for any change in geometry. The TekValsys DPrometer validation system is the better way to verify.

Why do we measure accurately?

Because Inaccurate measurement leads to:

Inefficiencies | Financial penalties | Legal arguments

Inefficiencies | Financial penalties | Legal arguments

So how do you know you are measuring accurately?

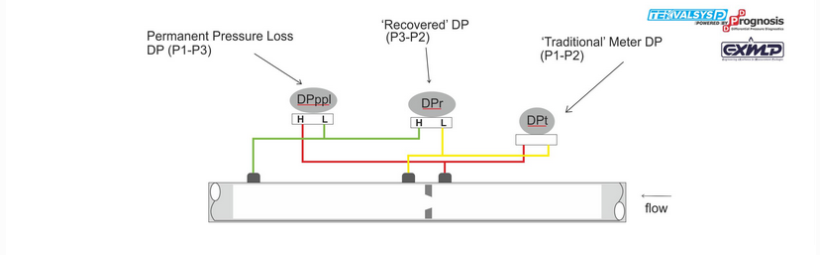

- By utilizing a third taping downstream of a meter body, it is possible to read three differential pressure measurements. These three DP measurements are the core of the Prognosis system, unlocking the full self-diagnostic capabilities of the meter.

- Using the three DPreadings, the pressure field through the meter is monitored and the three DPsare compared in multiple ways using other process conditions and metergeometry, providing powerful information on the meter’s performance using purely information which is already an integral part of Why do we need to measure Accurately? the meter without the need for any inspection.

– The diagnostic calculations are derived from well understood physical principles and industry standard calculations for DP meter flow rate. Seven diagnostic results are calculated and monitored in real time for each meter.

– The results are displayed as 4 points plotted on an 1×1 unitless box. Due to normalization (each comparison result is divided by its comparable uncertainty), if the meter is operating correctly to within its allowable uncertainties, each of the 4 points will be inside the box.

What Is TekValSys DPro?

Assurance of accuracy / compliance |Detection of meter system issues including:-

Incorrect Inlet /Throat Diameter in use, Saturated DP Transmitter, Incorrectly Spanned DP Transmitter, Two-Phase Flow, Drifting Transmitter Incorrect Discharge Coefficient, Excessive Upstream Disturbance, A Buckled Orifice Plate , Debris Trapped at Meter Throat, Contamination Build Up , A Worn or Damaged Office Leading Edge, Meter Incorrectly Instalment, Blocked Impulse Lines , A Damaged Cone Element

Incorrect Inlet /Throat Diameter in use, Saturated DP Transmitter, Incorrectly Spanned DP Transmitter, Two-Phase Flow, Drifting Transmitter Incorrect Discharge Coefficient, Excessive Upstream Disturbance, A Buckled Orifice Plate , Debris Trapped at Meter Throat, Contamination Build Up , A Worn or Damaged Office Leading Edge, Meter Incorrectly Instalment, Blocked Impulse Lines , A Damaged Cone Element

Application Areas- Single phase gas | Single phase liquid | Heavy Oil | WetGas | Water in Oil | Steam

TekValSys Variants’

| Trust PC | Micro | Cloud | ROC Platform | FCA | FloBoss / Omni |

© 2019 EXIMP

Design Made by Eximp Measurement Private Limited